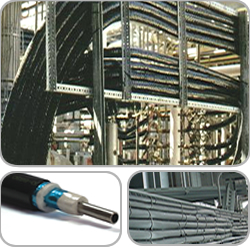

Pre-insulated tubing (ThermoTube)

More Information

Thermo Tube

pre-insulated tubing

Pre-insulated tubing for steam supply, condensate return, or other unheated fluid or gas transport.

Benefits:

- reduced installation time

- simplifies construction

- easy to bend and form

Browse our catalogues & add products of interest to your "enquiry list" or

contact us to discuss your requirements.

Thermo Tube

pre-insulated tubing

Pre-insulated with nonhygroscopic glass fibre, the tube is complete with a heat reflective foil wrap and a weatherproof outer covering. ThermoTube construction consists of a single insulated copper or stainless steel process tube ideally suited to transport

It was specifically developed for steam supply and condensate return lines, and is also used as an un-heated sample line. |

Advantages:

ThermoTube can also be manufactured in a variety of optional process tube materials, wall thicknesses and outer coverings to meet a multitude of applications. Specifications/ Ratings

ThermoTube termination kits protect the ends for a lower installed cost than field insulated tubing.

|

Listing

| Image | Name | |

|---|---|---|

|

Thermon ThermoTube SL: Pre-Insulated Tubing |

|