Thermowells, Thermocouple Pocket

More Information

to customer specifications:

|

|

contact us to discuss your requirements.

A Thermowell (also known as Thermocouple Pocket) isolates the temperature sensor from the process medium (gas, liquid...). This allows the sensor to be removed without compromising either the process or the environment.

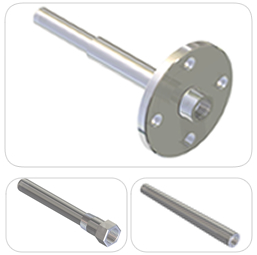

Types of thermowells

Thermowells can be

- solid drilled from bar stock

(no welded joints) or - fabricated from tubing

for less critical applications

- high pressure

- toxic or flammable substances

- when spillage is undesirable

- draining of vessels / pipes not feasible

Applications

- heating of air & gas

- heating of oil, water & other liquids

- heating of pipes & vessels

Thermowells selection guide

S T E M O P T I O N S |

||||

M |

STEPPED |

STRAIGHT |

TAPERED |

|

FLANGED |

|

|

|

|

THREADED |

|

|

|

|

VANSTONE |

|

|

|

|

WELD-IN |

|

|

|

|

SOCKET-WELD |

|

|

|

|

LIMITED-SPACE |

|

|

|

|

More info for selecting the appropriate thermowell

Diameter and length

The well dimensions should provide sufficient strength to withstand stresses imposed by vibration, pressure and flow. However, sufficient immersion length is necessary for accurate temperature measurement and a large diameter increases response time. It is thus a question of striking the best balance.

The biggest cause of thermowell failure is vibration due to flow of gas or liquid perpendicular to the thermowell ("von Karmann effect"). The natural resonant frequency of the thermowell (function of mass, diameter and length) should be kept well below the wake frequency of the fluid / gas. If the two frequencies coincide, the resultant vibration can cause mechanical failure.

Tapered or straight?

- Due to the higher strength to weight ratio, tapered thermowells are less prone to high frequency vibration than straight thermowells.

- The smaller tip provides faster thermal response.

- Stepped Thermowells provide similar performance to tapered thermowells.

- A straight body is thus mainly used on economically priced thermowells fabricated out of tubing.

Material

- Chrome / Moly steel: Used in industrial boilers.

Features: High strength, resistant to cleaning agents, chloroform, carbon disulphide - 304 Stainless Steel: Used in food and chemical processes, low cost.

Features: Corrosion resistant, low carbon grade, can be welded easily without affecting corrosion resistance. Maximum temperature: 900°C - 316 Stainless steel: Used in food and chemical processes. Features: excellent corrosion resistance due to added molybdenum, resistant to H2S, low carbon grade, can be welded easily without affecting corrosion resistance. Maximum temperature: 900°C

- 446 Stainless steel: Used in heat treatment processes, steel furnaces, gas production.

Excellent resistance to sulphurous atmosphere at high temperature. Good corrosion resistance to alkalis, sulphuric acid and nitric acid. Resistance to molten lead.

Note: low strength at high temperatures, should be mounted vertically. Maximum temperature: 1150°C - Inconel 600: Widely used in the Petrochemical and chemical industry.

High temperature strength, excellent corrosion resistance to chloride stress corrosion cracking. Can easily be welded.

Note: Vulnerable to sulphuric atmosphere above 500°C Maximum temperature: 1212°C - Monel 400: Widely used in sea water, ceramic processing and the chemical industry. Good corrosion resistance to acids (hydrofluoric, sulphuric, hydrochloric) and most alkalis. Can easily be welded. Maximum temperature: 538°C

- Hastelloy B3: Widely used in chemical processes involving Hydrochloric acid. Good resistance to pitting and stress corrosion cracking. Excellent resistance to hydrochloric acid in any concentration, resistant to sulphuric acid Can easily be welded. Maximum temperature: 1093°C

- Hastelloy C22: Widely used in chemical processes. Outstanding resistance to pitting and stress corrosion cracking. Good resistance to a wide range of chemical environments (ferritic and cupric chlorides, chlorine, acetic and formic acids, brine solutions and seawater. Can easily be welded. Maximum temperature: 1093°C

- Haynes alloy 556: Used in galvanizing processes, chloride salt baths. One of the few alloys that can survive in molten zinc. Also offers good resistance to sulphurising, carburizing and chlorine rich conditions. Maximum temperature: 1093°C

- Titanium: Widely used in offshore applications and seawater. Good resistance to oxidizing acids (nitric, chromic), resistant to inorganic chloride solutions, seawater and salt spray. Can be welded, precautions necessary to prevent atmospheric contamination.

View corrosive materials guide here >>

[feedback]